Professional and home chefs alike will be quick to tell you that Japanese knives are some of the best in the world, especially those made in Niigata Prefecture’s manufacturing region of Tsubame-Sanjo. As the same suggests, the region is made up of Tsubame City and Sanjo City, two small cities which share a Shinkansen station and a wealth of talented artisans. Although Tsubame is well-known for its cutlery and copperware while Sanjo City excels in blacksmithing, both are respected in kitchens across the world for their excellent cooking knives. But before this region made knives, they made nails.

As a flatland between a high-reaching mountain range to the east and the Sea of Japan to the west, Tsubame-Sanjo would presumably have been an ideal place for growing rice. However, this region is cut through by the Shinano River, the longest and one of the fastest flowing rivers in Japan, which frequently flooded the plain and made it difficult to farm. After the area suffered flooding and famine in the early 17th century, Otani Seibei, the Edo-government appointed magistrate of this region, brought blacksmiths from the capital of Edo (now Tokyo) to teach the impoverished farmers metalworking, and specifically how to make wakugi (Japanese nails). These nails were used in the construction of houses, temples, castles, and, as of 1991, the holiest of all Japanese shrines: Ise Jingu in Mie Prefecture.

During the 17th and 18th century, a number of massive fires in Edo further drove the demand for wakugi and solidified Tsubame-Sanjo’s status as an area for quality ironworks. At the same time, flood-prevention methods improved, allowing for farming to take off in Niigata and across Japan. With that, craftsmen shifted from nails to farming tools such as scythes, sickles and saws, and those techniques transitioned into today’s cooking knives.

Nowadays, famous knifemakers such as Global and Tojiro can be found in Tsubame, while Tadafusa and Shimomura knife factories are located on the Sanjo side.

Tsubame and Sanjo are (rightfully) very proud of their craftsmanship, and you can see this reflected in major ways across both towns. If you arrive by Shinkansen—just under 2 hours from Tokyo Station, or only an 8 minute ride from Niigata Station!—the first thing you’ll see when you pass through the station gates is a miniature museum that beautifully displays local products. There are a number of open factories and museums in both towns that deserve attention, as well as the annual Tsubame-Sanjo Factory Festival, where around 100 businesses welcome visitors to their factories to introduce their techniques and manufactured wares.

In Tsubame, the Tojiro Open Factory is worth a visit for anyone who has an interest in cooking knives. At this modern factory, you can see mass-produced kitchen knives cut from single sheets of steel for the casual cook, and the atelier is where craftspeople lovingly create professional-grade knives by hand.

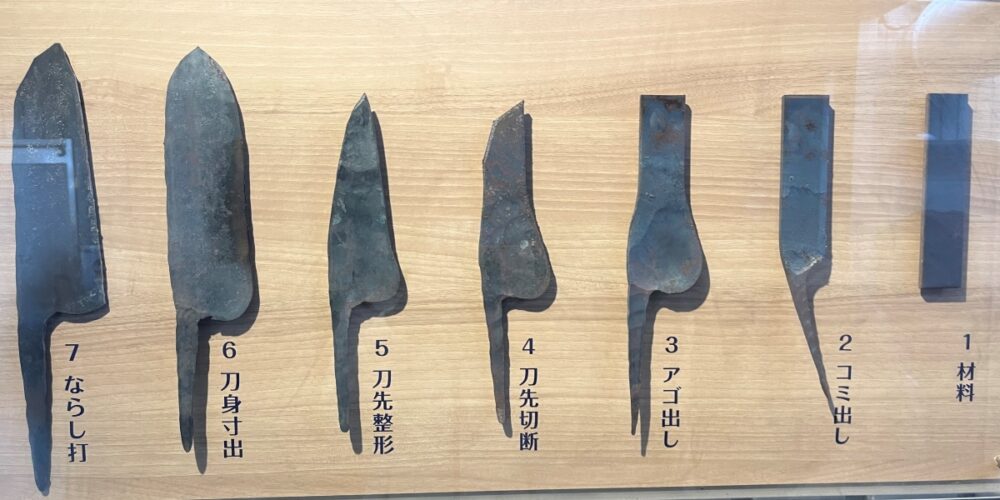

Hand-crafted knives go through about 16 steps from start to finish. First, a rectangle of iron layered with thin sheets of different alloys is heated to around 1500 degrees Celsius in a brick oven in the forging cabin. Once the rectangle is red hot, a stamp-machine operated by an artisan quickly hammers it out into a familiar shape of a knife. Interestingly, the bottom of the handle is bent upward while the knife is being forged—this makes it easy to pick up if it is dropped!

After forging, the knife is taken to the atelier, where it goes through about 11 more steps before it is completed. After the rough shape is finished, the edge is cut, and then the knife is formed with a lathe to “shape up” the blade and make it uniform. This is followed by a heat treatment, and then the edge of the knife whittled down further before the handle is attached and polished. The second-to-last step is the engraving of the company name on the flat side of the knife. This is the most nerve-wracking part, as any mistakes cannot be undone or repaired by that point, but even with the distraction of tourists, these steely-handed pros are unbothered and are happy to show you their skills. Finally, the blade is sharpened one last time against grindstones of varying grit to ensure a perfectly sharp cut.

Although cutlery and kitchen knives are things most of us use every day, we may not consider the processes used to create them, or the places they were made. Tsubame-Sanjo is an area that truly respects the history and quality of their crafts, and is a great look into the manufacturing processes of these everyday goods. Next time you’re picking out a kitchen knife, I hope you’ll think of this corner of Niigata, and treat yourself to a quality piece you can use for years.

About the Author:

Hi, I’m Katelyn, an American living and working in Niigata City. I moved here from Aichi Prefecture in September 2021, and I hope to enjoy my short time here to the fullest! With its bountiful nature, delicious local food and fun things to do in all seasons, I feel that Niigata is truly a great place to visit, and an even better place to live. https://www.instagram.com/windowtojapan/