Gyokusendo

In 1816 the future founder of Gyokusendo started his own workshop. The master and later his company specialized in copper tableware. Their workshops and showrooms are located in an amazing traditional Japanese building, where the company has been located for nearly 100 years. Walking those halls, one feels inspired and connected to the great masters that came before.

Or in my case, one tries to feel those things, as they ruthlessly swing a hammer.

Or in my case, one tries to feel those things, as they ruthlessly swing a hammer.

I was privileged to experience one of the rare events that are held at Gyokusendo. I was challenged with creating a copper drinking cup, completely from scratch!

Step 1:

First, you get a round piece of copper, about the size of good, self-respecting coaster. Using a big wooden mallet and a slightly bowl-like shape is given to the copper.

- From the very start we were in great hands! One of the craftsman is explaining how to get started. These young people work at Gyokusendo full time. Here, they get the awesome chance to perfect their skills!

- The original “coaster”

Step 2:

Using the thin pencil line as a guide, the future cup is slowly shaped.

An interesting quality of copper – although it is considered a relatively soft metal, hammering makes it really hard. However, when it is fired and then suddenly cooled, copper becomes soft once again.

That is why, as I was working on my future cup, every so often it was necessary to really heat things up!

Step 3:

Giving it the nice silver shine!

Once it has been given the desired shape, the outside of the cup is covered in clay. Then the cup is heated up and tin is melted on the inside! (Tin works well, because it light, has a melting point far below copper and with proper treatment can get nice and shiny!)

Step 4:

The cup must be polished! The edges have to be filed down for safety (and let me tell you…mine were sharp!). The outside also must be polished to make the next step more successful!

Step 5:

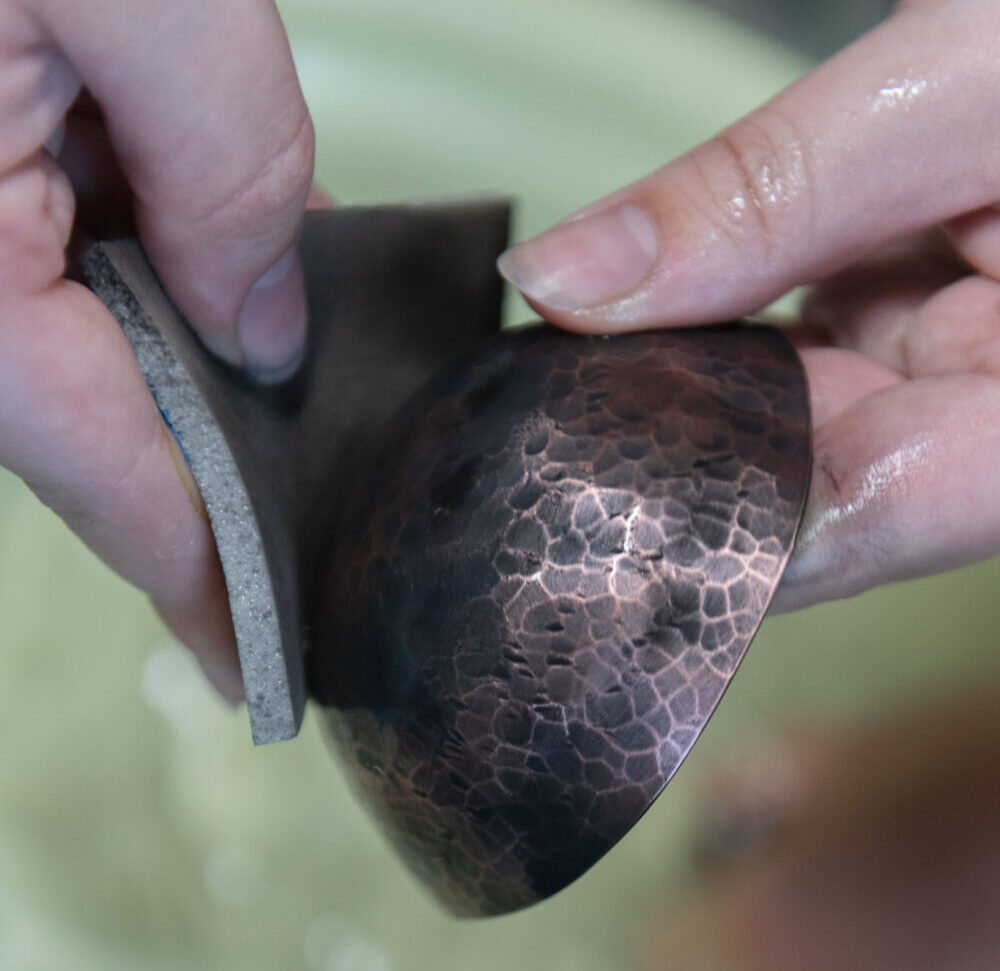

To create an amazing variety of colour and texture, the copper is oxidized in various chemicals. This time potassium sulfate (element commonly found in hot springs!) was used to darken the copper!

Once the colour has changed, some additional polishing on the outside will reveal the (questionable in my case) hammer technique of the craftsmen.

- The colour changes depending on how long the cup is immersed in the solution. It is a lot more difficult than it looks too! Have you ever tried to keep a cup face-down in a liquid without the cup flipping?

Afterward, a thin layer of natural wax is melted and spread on the outside surface to protect the cup from moisture. Apparently, this layer eventually fades but will help the colour change more evenly and increase the shine as you use it over time!

Honestly, this was one of the most impressive things I have done in my life! It took only 3 hours, to go from metal coaster to a proper cup. Which was completely unbelievable. The aches and pains the next day made me truly realize the amount of effort that must be put into the creation of one of these table pieces.

That is not to mention the skill and concentration and love of your craft.

I should mention, that although I speak easily of the process, none of it was! The expert craftsmen of Gyokusendo were with me every step of the way and without them all would have been lost… or rather flat and useless.

For more information about this amazing collective of craftsmen and much more please visit THEIR WEBSITE

|

Jenya Yuss came to Japan in 2015 and has not left since. She has lived in Nagoya, Ishikawa and finally settled in Niigata. She loves to be in nature and enjoys all types of outdoor activities. She likes to write about history and culture, but really would tackle any topic! |